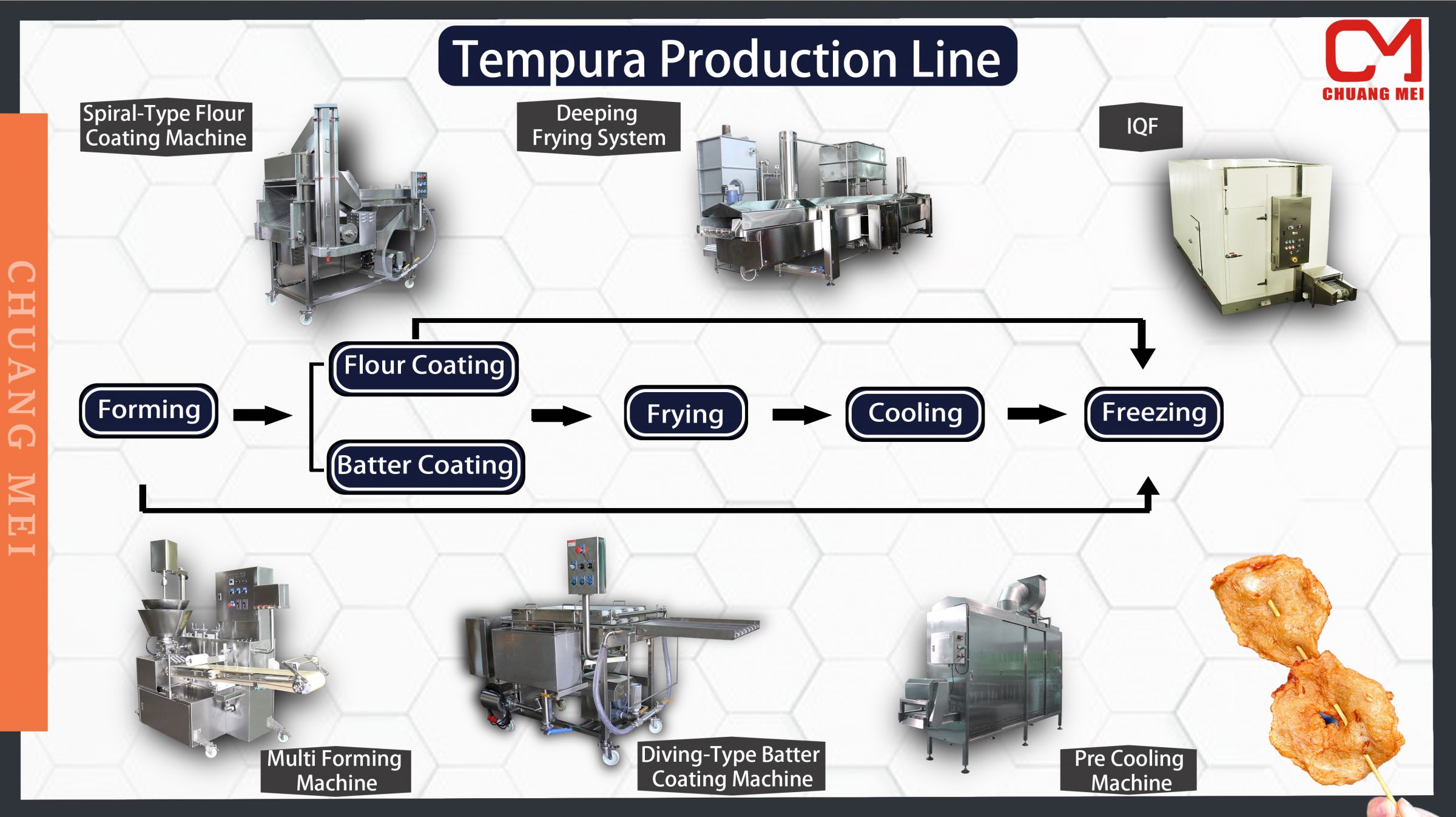

Tempura Production Line

Fried Tempura、Fish cake、Production Planning Proposal and Equipment Application of Tempura

Tempura is a processed aquatic food made of fish paste and starch. It often appears in fried food and Oden. It uses Chuang Mei 's Multi Forming Machine, and is equipped with Automatic Batter & Breading Lines , Continuous Frying Machine, and Food Refrigeration Cooler Machine, and you can easily make Tempura products.

Tempura Production Line

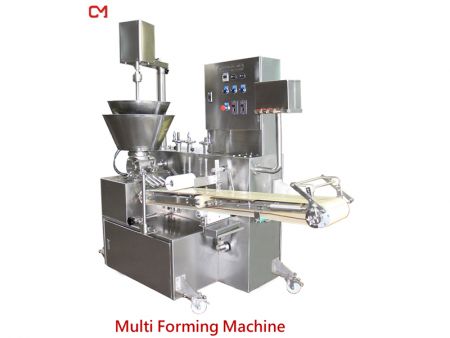

⚫️Filling & Forming-Multi Forming Machine:Multi Forming Machine can be used to make food of various shapes and sizes. The multi-purpose mechanical design of one machine is not only high precision, but also made of stainless steel for the entire machine. It is easy to disassemble and clean.

⚫️ Flour Coating-Spiral-Type Flour Coating Machine:Spiral-Type Flour Coating Machine is a continuous spiral conveying powder coating from bottom to top, suitable for any powder, can be coated with fine powder or coarse powder.

⚫️ Batter Coating-Diving-Type Batter Coating Machine:Diving-Type Batter Coating Machine is suitable for denser batter. It immerses the product in the slurry to coat the product with a layer of powder, which is convenient for operation and adjustment.

⚫️Frying-Deeping Frying System:This machine can directly heat the oil consumption by 25 - 45% compared with the general furnace body, and provides a continuous filter to quickly filter the oil to maintain the quality of the oil, and the oil temperature can be used for the temperature between the product inlet and outlet through external heating Variations, and multiple heating zones can be added to provide precise temperature control. The machine has an automatic lifting function.

⚫️Cooling-Pre Cooling Machine:The machine has good air convection and cooling efficiency, and the door panel can be opened and closed, which is convenient for cleaning.

⚫️Freezing-IQF:It is divided into tunnel type and spiral type. It is extremely easy to automate arrangements in the production line, it can greatly reduce the use of manpower and improve productivity.

CHUANG MEI has more than 40 years of experience in food processing and conditioning machinery manufacturing and whole plant planning. We can provide customized services according to customer needs to solve customer process problems. If you have any needs, please feel free to contact us.

- Related Products

Multi Forming Machine

Multi Forming Machine can be used to make food of various shapes and sizes. The multi-purpose...

DetailsBatter Coating Machine

Batter Coating Machine is divided into Diving-Type Batter Coating Machine and Waterfall-Type...

DetailsFlour Coating Machine

Flour Coating Machine is divided into Rotary-Type Flour Coating Machine and Spiral-Type Flour...

DetailsContinuous Frying Machine

The Continuous Frying Machine is made of stainless steel, which meets the requirements of food...

DetailsPre Cooling Machine

Chuang Mei's Pre Cooling Machine is a five-layer T-net conveyor belt with good cooling effect,...

Details

Tempura Production Line - Fried Tempura、Fish cake、Production Planning Proposal and Equipment Application of Tempura | 45 Years Food Forming, Coating & Cooking Machinery Manufacturer Since 1977 | CHUANG MEI INDUSTRIAL CO.

Based in Taiwan since 1977, CHUANG MEI INDUSTRIAL CO. has been a food processing machinery manufacturer. Their main processing machines, including Tempura Production Line, food forming, coating, frying and cooking machinery, as well as food refrigeration coolers, conveyors and lifter equipment.

CHUANG MEI Industry has more than 45 years of experience in food processing machinery manufacturing. It has complete self-development ability, provide customized and accurate humanistic consideration design, and are consistent with comprehensive, formal and multi-functional opportunities. CHUANG MEI focuses on producing of aquatic food processing and conditioning machinery and offering friendly services to customers.

CHUANG MEI, CM has been offering customers food cooking machines, both with advanced technology and 45 years of experience, CHUANG MEI, CM ensures each customer's demands are met.